(Please read the print settings post first)

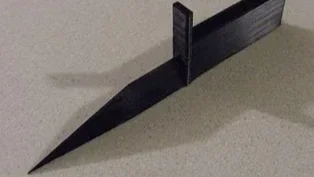

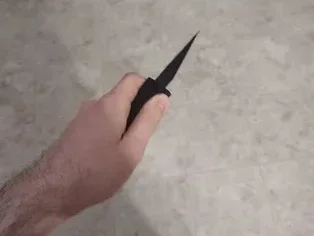

I designed a 3D printable knife that is thin and able to be concealed. Print at 100% density infill. Put metal wires into the holes to make sure it can be detected by metal detectors. Sand down the sides so that it is smoother and sharper. I also made a holster for the knife. Print the holster at 25% density infill. Follow all pertinent laws.

LBRY Tags: 3d printing; invention; knife; weapons

u/GodzillaFlamewolf · 2023-12-21 06:47:14 UTC · score 3

The problem isn't difficulty, it is time. So here is the order of operations for any given panel, say a side grip panel:

- Select all faces making up the area to which you want to apply a patern.

- Copy those faces and move them away from the original object along a fixed axis.

- Copy tha…

u/rainingpouring6500 · 2021-08-09 21:20:53 UTC · score 2

Lots of directions you could take this I think. My illustration is about as simplistic as it gets but that cutting tool could be just about any shape you wanted, plus include holes and all sorts of stuff. The copper wire would be an option, but personally I think I would go with conductive…

u/M18PuffcoPeak · 2023-02-27 02:23:37 UTC · score 26

Honestly, while these dimensions are nice. There's a grabcad model that I modified and you can buy a flat bending jig off of GB to press it. The original flats weren't heat treated but if you use 10 gauge 4130 sheet metal, you can heat treat it afterwards in a large enough 120v knife kiln and some…

Striker Pocket

Everyman Folding Knife

3D Printable Dagger