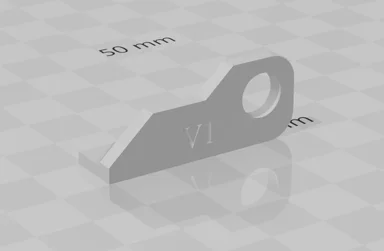

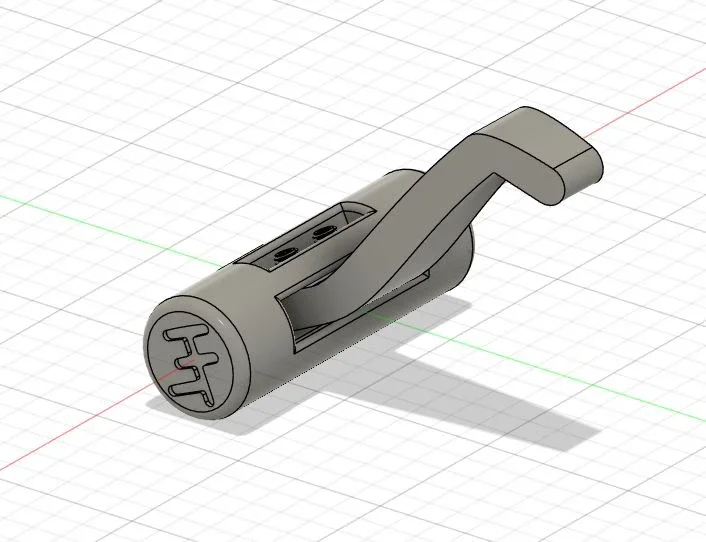

This is intended to be a CNC-capable variant of Tim Hoffman's Super Safety, so it can be milled from metal.

I have NOT tested it with an actual CNC machine yet, I've only 3D printed a prototype. It works by retaining the lever in the cam using two headless screws (#2-56 3/16in, see Amazon link). My assumption was that the original Super Safety can't be CNC'd because it has "cavities" that a machine couldn't reach, so I tried to modify it to remove those cavities or make them more accessible. There might be some further adjustments needed, like increasing the screw sizes, reducing some of the tolerances, etc. Please comment to let me know if anyone successfully CNCs using this, and if any adjustments were needed. I can also help adjust them.

Screws: https://www.amazon.com/Socket-Screw-Point-Stainless-Steel/dp/B00FAV5N1A

Update 5/1/2024: Modified internal edges to be curved

Super Safety Go/No Go Gauge

Krrawn's Boarder SCS Trigger

Gspot FRT Flat trigger shoe