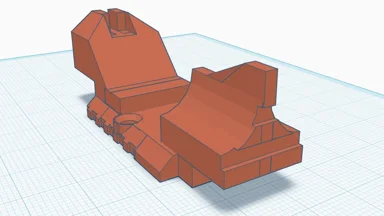

XMacro Backstrap Brace Adapter — Free File (Seeking Constructive Criticism)

This is a custom backstrap adapter I designed in Tinkercad for the P365 XMacro platform. I’m fairly new to CAD (this was my learning project), and I’m releasing the STL for free — all I ask in return is honest, constructive feedback.

Quick summary

Designed in Tinkercad and iterated through multiple versions.

Printed in Polymaker PA12-CF and shot with the adapter installed — it held up fine in testing.

I reinforced the takedown-pin hole with a hot staple using a plastic welder to improve durability.

If you try this, feel free to improvise the rear takedown pin (see below). The original backstrap pin from your grip module can be reused.

Design & build notes (what I actually did)

Instead of the regular rear takedown pin I used a 3 mm stainless steel rod (~34 mm long). I chucked it in a drill and ground it down to fit, then ground a groove for the spring to sit in.

For folks 3D printing: you can improvise for that pin with whatever you have (brass rod, steel rod, etc.). The backstrap pin included with many grip modules can also be reused.

To reinforce the hole where the rear takedown pin passes through, I used a plastic welder and installed a hot staple — this significantly strengthened the area under repeated use.

Iterations / lessons learned

I went through about 7 variations before landing on the current design.

Early versions had a failure mode where the adapter would separate/break at the rear where the takedown pin sits.

Later designs that tried to solve that by adding material ended up too bulky, which made racking the slide awkward — you could only rack by grabbing the optic or the front slide serrations.

The current balance aims to be strong at the takedown area while keeping the adapter slim enough to allow normal slide manipulation.

What I tested

Material: Polymaker PA12-CF (carbon-fiber nylon).

Function: Installed and fired — the adapter remained intact and functional during testing.

Reinforcement: Hot-staple + plastic welding around the takedown hole for longevity.

What I’m asking from you (constructive feedback)

If you download and test this free file, please consider reporting back on:

Fitment: any gaps or tight spots when installed.

Durability: any cracking, deformation, or wear after range use.

Function: does the slide rack normally? Any interference with optics or slide serrations?

Improvements: suggestions to reduce bulk while keeping strength, or alternative reinforcement methods that worked for you.

Printing notes: recommended slicer settings, infill, orientation, or post-print finishing that improved the part.

Assembly / user tips

You don’t need to replicate my exact pin — improvise with what you have (brass rod, steel rod, reuse the original backstrap pin).

If you plan to use the part regularly, consider reinforcing the takedown pin hole (I used a hot staple + plastic welding with good results).

Expect some minor hand-finishing/tuning depending on your printer tolerances and the rod you use for the pin.

Final notes

This was made as a practical prototype and learning project — not a polished production design. I’m releasing the STL for free because feedback from real users is what I want most. If you try it, please leave detailed notes

Yah3D SIXHOUR P365XL Grip Module for Manual Safety

GLOCK Magazine Holster Package 2

ForkAerospace's PY2A G69 Remixes