View this release

Alternative links

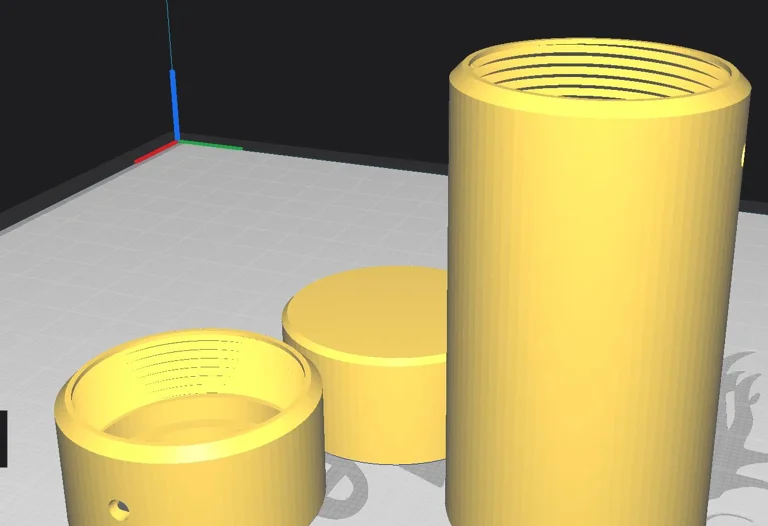

A couple test prints for the EZ22 using a shortened barrel nut sleeve. One is designed for testing how well it screws on and the other tests fitment inside the handguard. This should help you calibrate your prints.

Print recommendations:

Orientation: threads up (default)

Walls: 3+

Infill plug: 15%+, less will be easier to destroy to remove from handguard but may not fit as accurately. Disc shaped to de easily shoved out with an object.

Infill Screw: user choice

Pro tip:

For screw it is better to define a z seam location as co-ordinates to get consistent alignment and prevent stringing from crossing the bore.

**Updated to fix screw test**

LBRY Tags: art; ez22; fosscad; 3d print; calibration

Print recommendations:

Orientation: threads up (default)

Walls: 3+

Infill plug: 15%+, less will be easier to destroy to remove from handguard but may not fit as accurately. Disc shaped to de easily shoved out with an object.

Infill Screw: user choice

Pro tip:

For screw it is better to define a z seam location as co-ordinates to get consistent alignment and prevent stringing from crossing the bore.

**Updated to fix screw test**

LBRY Tags: art; ez22; fosscad; 3d print; calibration