View this release

Alternative links

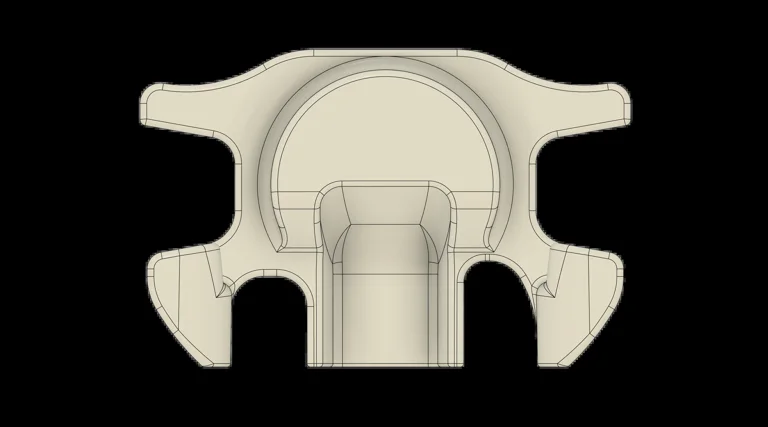

Slip Trip V3

---------Description---------

The slip trip is nothing more then a trip "bar" for the MP5 platform that enables most

if not all mp5s and clones to work with ar15 parts that require a full auto bolt carrier

like the super safety or SFFA.

The slip trip functions by sliding on the rails of the receiver while being pulled by the

bolt carrier, it doesn't require any special modifications and will work with any bolt

carrier including semi only cut BCs. When a round is fired and the bolt carrier comes

back the slip trip will collapse on itself so it wont have any noticeable affect on

rate of fire, recoil impulse and will not create additional wear on the receiver.

Huge credit goes to hertzofheimer and meatbanana42069 for their original designs

and feedback that has enabled this version to exist. This was created from the Trip

clip step file and other files from that pack have been referenced for measurements.

----------Warning about metal slip trips------------

The printed slip trip is designed around pla pro not metal so making it

in metal will end up making it weigh at least 6x as much as one printed

in pla pro. The durability of a printed slip trip should be well past

1000 rounds even with below average print settings. Good print

settings in something like nylon that is printed slow, hot and then

annealed should outlast any metal SS cam currently on the market.

This added weight from making the slip trip in metal can cause the

slip trip to slam forward into the lever potentially damaging the SS

lever or CAM. I would recommend you all to just print slip trip in PLA

pro or nylon as intended. Regardless of what i say i know people will

attempt to have them made in metal so i will be releasing a metal

version on my odysee @s3igu2 so look around for that version if you

must make it in metal. That said please do not attempt to make the

version of this slip trip in this pack in metal.

-------Disclaimer---------

Note: that if your are using a AP5 or AP5K the slip trip will most likely need to be

filed in some areas to fit past the full auto bolt carrier group block.

-------Materials Required-------

The Slip trip will require about 15 grams of PLA Pro filament no additional hardware is needed

-------Print Settings-------

Everything is designed to work in PLA Pro or Polymaker PA6-CF

if you want a more high temp option, see my odysee guide

@s3igu2 for exact settings if you plan to print in polymakers pa6-CF.

STL files are orientated correctly and have brims / supports where needed

(STEP files are NOT orientated correctly)

Temp: 220/60C (PLA PRO)

Nozzle: 0.4mm

First Layer Height - 0.20 (Or 0.15)

Layer Height - 0.15

Wall Loops - 4 Walls Max

Infill - 100% Rectilinear

No supports are needed on any of the parts unless you use the "No Support" version of

the housing or the "No Brim" version of the selector located in the Other folder

---------Description---------

The slip trip is nothing more then a trip "bar" for the MP5 platform that enables most

if not all mp5s and clones to work with ar15 parts that require a full auto bolt carrier

like the super safety or SFFA.

The slip trip functions by sliding on the rails of the receiver while being pulled by the

bolt carrier, it doesn't require any special modifications and will work with any bolt

carrier including semi only cut BCs. When a round is fired and the bolt carrier comes

back the slip trip will collapse on itself so it wont have any noticeable affect on

rate of fire, recoil impulse and will not create additional wear on the receiver.

Huge credit goes to hertzofheimer and meatbanana42069 for their original designs

and feedback that has enabled this version to exist. This was created from the Trip

clip step file and other files from that pack have been referenced for measurements.

----------Warning about metal slip trips------------

The printed slip trip is designed around pla pro not metal so making it

in metal will end up making it weigh at least 6x as much as one printed

in pla pro. The durability of a printed slip trip should be well past

1000 rounds even with below average print settings. Good print

settings in something like nylon that is printed slow, hot and then

annealed should outlast any metal SS cam currently on the market.

This added weight from making the slip trip in metal can cause the

slip trip to slam forward into the lever potentially damaging the SS

lever or CAM. I would recommend you all to just print slip trip in PLA

pro or nylon as intended. Regardless of what i say i know people will

attempt to have them made in metal so i will be releasing a metal

version on my odysee @s3igu2 so look around for that version if you

must make it in metal. That said please do not attempt to make the

version of this slip trip in this pack in metal.

-------Disclaimer---------

Note: that if your are using a AP5 or AP5K the slip trip will most likely need to be

filed in some areas to fit past the full auto bolt carrier group block.

-------Materials Required-------

The Slip trip will require about 15 grams of PLA Pro filament no additional hardware is needed

-------Print Settings-------

Everything is designed to work in PLA Pro or Polymaker PA6-CF

if you want a more high temp option, see my odysee guide

@s3igu2 for exact settings if you plan to print in polymakers pa6-CF.

STL files are orientated correctly and have brims / supports where needed

(STEP files are NOT orientated correctly)

Temp: 220/60C (PLA PRO)

Nozzle: 0.4mm

First Layer Height - 0.20 (Or 0.15)

Layer Height - 0.15

Wall Loops - 4 Walls Max

Infill - 100% Rectilinear

No supports are needed on any of the parts unless you use the "No Support" version of

the housing or the "No Brim" version of the selector located in the Other folder