View this release

Alternative links

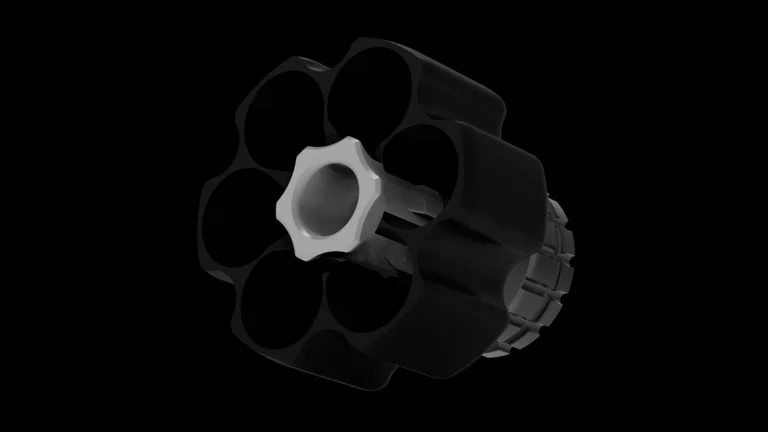

Laffs K Frame Speed Loader V2.0.1: Laffs Dynamics

A K Frame speed loader, designed with V2 features of the Laffs J Frame Speed Loader. Specifically for 6rd, .38Spl/.357Mag revolvers such as the S&W Model 10, and Model 19.

V2 Features Include:

*Reduced cartridge release knob turn of 30 deg, instead of 35deg.

*New cartridge retention spindle that now interlocks with the release knob.

*Longer cartridge holder, spindle, and release knobs for better control when feeding into a revolver

cylinder.

Printer Used: Ender 3 V2

Filament Used: PLA+

Print Settings:

Extruder: 218C

Bed: 56C

First Layer Print Height: .20mm

Standard Layer Height: .12mm

Wall Thickness: .40

Wall Perimeters: 5+

Infill: 32%

Support Material Percentage: 20%

Support material only needed for the detent channel at the bottom of the cartridge holder, and under the mechanically

compliant spring/catch on the release knob.

Hardware Required:

1x M3x12mm Hex Screw

Accreditations:

Freeman1337: Printed and assembled the speed loader. Tested with multiple live and dummy rounds. Provided images of multiple

loaders. Gave info that led to reduction in cartridge release turn angle and over-rotation.

LBRY Tags: 3d printing; firearms; k frame; speed loader; ammo

A K Frame speed loader, designed with V2 features of the Laffs J Frame Speed Loader. Specifically for 6rd, .38Spl/.357Mag revolvers such as the S&W Model 10, and Model 19.

V2 Features Include:

*Reduced cartridge release knob turn of 30 deg, instead of 35deg.

*New cartridge retention spindle that now interlocks with the release knob.

*Longer cartridge holder, spindle, and release knobs for better control when feeding into a revolver

cylinder.

Printer Used: Ender 3 V2

Filament Used: PLA+

Print Settings:

Extruder: 218C

Bed: 56C

First Layer Print Height: .20mm

Standard Layer Height: .12mm

Wall Thickness: .40

Wall Perimeters: 5+

Infill: 32%

Support Material Percentage: 20%

Support material only needed for the detent channel at the bottom of the cartridge holder, and under the mechanically

compliant spring/catch on the release knob.

Hardware Required:

1x M3x12mm Hex Screw

Accreditations:

Freeman1337: Printed and assembled the speed loader. Tested with multiple live and dummy rounds. Provided images of multiple

loaders. Gave info that led to reduction in cartridge release turn angle and over-rotation.

LBRY Tags: 3d printing; firearms; k frame; speed loader; ammo