View this release

Alternative links

OPEN BETA TEST - USE FILES AT YOUR OWN RISK - PLEASE PROVIDE ALL FEEDBACK, GOOD, BAD, OR OTHER.

THIS IS NOT A FIREARM COMPONENT AND CANNOT BE READILY ADAPTED TO BE

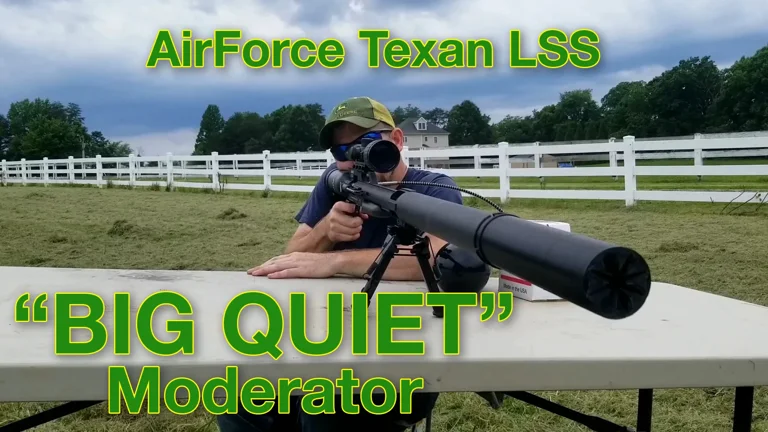

Open Beta test of my AirForce Texan LSS Moderator.

Read the readme.txt file.

Included are three different shells with the same internals. The hose clamp shell is designed to use a #24SAE Hose clamp for additional support. I recommend Black Oxide. The screw clamp is based off Alpha feedback that some ranges wouldn't allow hose clamps (sounds like the RSO needs an upgrade to me, but whatever). That one uses 2x M4x20 socket cap screws. During destructive testing, I discovered that no matter what pressure or slug weight I used in a .457, the threads held fine, so I added a slickside variant to look a little prettier.

I have tested the .457 versions in eSun ProPLA with and without annealing.

It *might* work on a standard SS. I don't have one to test with.

Print Instructions:

Print vertically with Muzzle end down, no supports.

eSun ProPLA (PLA+) is a minimum. If you can print PC or Nylon, that's probably even better. Print hot and slow. I used a Creality Ender 5 at 235 Nozzle, 65 Bed, 50mm/S, 100% infill. Sand annealing is recommended, but not required.

If you print these, please be sure to provide feedback to me (@CVABuck on Odysee, Thingiverse, or Twitter and let me know your thoughts. In particular, I'm interested in objective testing versus the stock moderator and/or DonnyFL moderators. If you provide feedback, please include the following data along with your feedback:

Material used

Caliber/shell style printed

These files are covered by the martian license - treat them like they came from another planet. You can do what you like to them, but you also assume all risk associated with using them in any way.

LBRY Tags: 3d printing; airforce texan; airforce airguns; airgun moderator; texan lss

THIS IS NOT A FIREARM COMPONENT AND CANNOT BE READILY ADAPTED TO BE

Open Beta test of my AirForce Texan LSS Moderator.

Read the readme.txt file.

Included are three different shells with the same internals. The hose clamp shell is designed to use a #24SAE Hose clamp for additional support. I recommend Black Oxide. The screw clamp is based off Alpha feedback that some ranges wouldn't allow hose clamps (sounds like the RSO needs an upgrade to me, but whatever). That one uses 2x M4x20 socket cap screws. During destructive testing, I discovered that no matter what pressure or slug weight I used in a .457, the threads held fine, so I added a slickside variant to look a little prettier.

I have tested the .457 versions in eSun ProPLA with and without annealing.

It *might* work on a standard SS. I don't have one to test with.

Print Instructions:

Print vertically with Muzzle end down, no supports.

eSun ProPLA (PLA+) is a minimum. If you can print PC or Nylon, that's probably even better. Print hot and slow. I used a Creality Ender 5 at 235 Nozzle, 65 Bed, 50mm/S, 100% infill. Sand annealing is recommended, but not required.

If you print these, please be sure to provide feedback to me (@CVABuck on Odysee, Thingiverse, or Twitter and let me know your thoughts. In particular, I'm interested in objective testing versus the stock moderator and/or DonnyFL moderators. If you provide feedback, please include the following data along with your feedback:

Material used

Caliber/shell style printed

These files are covered by the martian license - treat them like they came from another planet. You can do what you like to them, but you also assume all risk associated with using them in any way.

LBRY Tags: 3d printing; airforce texan; airforce airguns; airgun moderator; texan lss