View this release

Alternative links

Released 06Jan2025

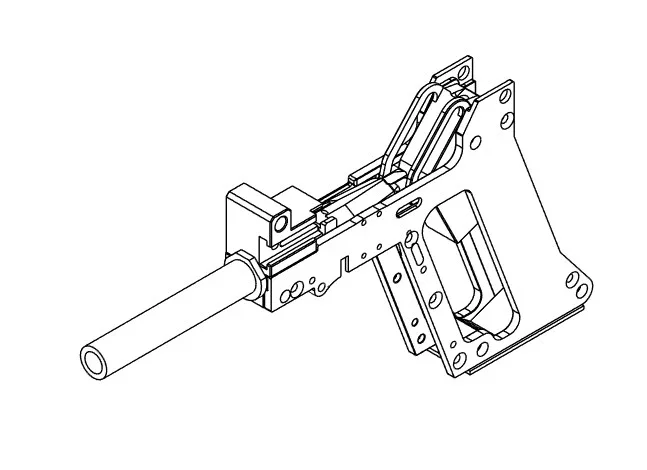

V'sSlidiBoi (Machinist Edition) © 2025 by AndYouMayCallMeV is licensed under CC BY-NC-SA 4.0

This CAD is based directly off of measurements from two Kriss Vector samples in 9mm and 45ACP. They have been tested to confirm function.

If you manufacture this in any sort of polymer, it will fail after 1-4 rounds based on testing. These MUST be manufactured in 4140 or better. The original Vector receiver is riveted/swaged together, but a similar sized spacer and screw will work.

If you find any errors in the CAD or would like to assist in creating a DIY receiver/Upper, please let me know ASAP @ jkilian@3dprintfreedom.com and I will get the adjustments made ASAP.

Required legal/readme:

1. I don't guarantee these files will work for you.

2. I don't guarantee your self-made parts won't blow up. Please use all reasonable safety precautions.

3. Machining is all about tolerance. Keep them tight, but not too tight.

4. Please see the CC license

V'sSlidiBoi (Machinist Edition) © 2025 by AndYouMayCallMeV is licensed under CC BY-NC-SA 4.0

This CAD is based directly off of measurements from two Kriss Vector samples in 9mm and 45ACP. They have been tested to confirm function.

If you manufacture this in any sort of polymer, it will fail after 1-4 rounds based on testing. These MUST be manufactured in 4140 or better. The original Vector receiver is riveted/swaged together, but a similar sized spacer and screw will work.

If you find any errors in the CAD or would like to assist in creating a DIY receiver/Upper, please let me know ASAP @ jkilian@3dprintfreedom.com and I will get the adjustments made ASAP.

Required legal/readme:

1. I don't guarantee these files will work for you.

2. I don't guarantee your self-made parts won't blow up. Please use all reasonable safety precautions.

3. Machining is all about tolerance. Keep them tight, but not too tight.

4. Please see the CC license