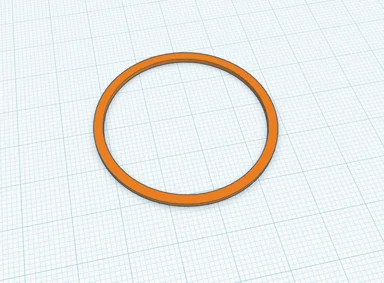

209 and ramset base for 37mm shells. Uses 1.5" od .065" wall steel tube (or whatever other material, I suppose) for the sleeve. Be safe and shit. Based on shells available in the "Consolidated 37mm Ammunition File Pack" . All I did was a quick mod, all credits go to the original creators.

LBRY Tags: 37mm; launcher

I see your problem now. If you are only using these for blanks, with primer only, you could probably use a more rigid material such as PETG. Although something such as PA-CF or PLA-CF might do the trick, I would avoid filled materials because they are abrasive. I have had similar thoughts about adding a steel pin for the anvil in other projects, but since I have started using the primer bar, I have had no reliability issues. This won't work for …

u/Mr_B34n3R · 2024-03-09 05:09:20 UTC · score 19

If you don't have an enclosure, you should get one. Hardened steel nozzle or similar. Some plans for annealing and using oil based polyurethane coats to prevent excessive flexing.

Some will say that using the coat will make the part stiff, but you can wait a few days for the part to absorb some water and…

u/Advanced-Payment-358 · 2022-07-25 18:42:52 UTC · score 15

We already have, not just rigid enough to effectively cut tool steels and high strength alloys. You still need to learn how to program and use one, and all of the accessory it requires, and getting/making specific jigs and mounts for parts, re-mounting and dialing them in, etc. Oh boy…

37mm Nameless

PoopShitter

PoopHitter