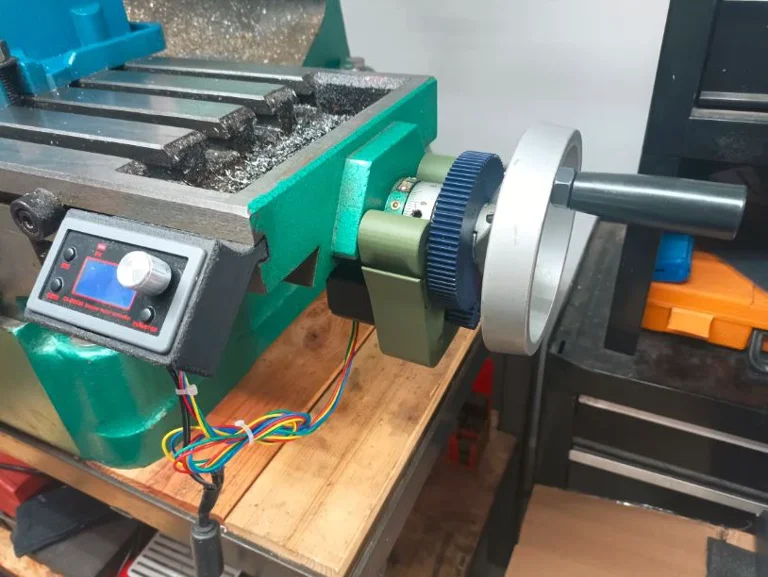

This power feed was designed for the x-axis on a Harbor Freight Model 33686 Round Column Milling/Drilling Machine, but it should also work on the nearly identical Grizzly G3358.

I used a ZK-SMC02 Stepper Motor Driver (~$9 on Aliexpress, ~$29 on amazon), and a NEMA17 KL17H272-20-4A (124oz-in) stepper motor. With the 1:4 gear ratio, each full step on the motor is 0.000125” on the x-axis, but I’ve got the stepper motor driver dip switches configured for 1/32 microstepping to allow for the slowest feed speeds I would want.

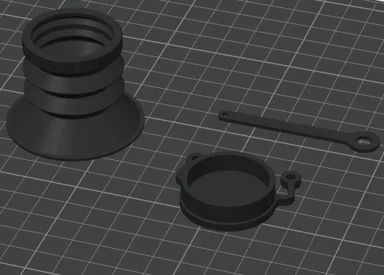

I printed with e-sun PLA+, 8 top and bottom layers for the sides of the gears, and three perimeter walls. 15% adaptive cubic infill.

The bolts holding on the lead screw flange were torqued fairly tight and I didn’t want to rely solely upon compressive strength of the plastic mount to hold it securely in place, so this was designed to only replace one of the two bolts that holds that flange on. The other side of the power feed mount should be tapped for a 10-24 set screw, which pokes into the allen head on the other existing lead screw flange bolt to keep the entire mount from rocking.

• You’ll need to get the same diameter metric bolt to replace the one lead screw flange bolt, which is about 1.3” longer than the original to bolt through the mount and lead screw flange

• I used a 10-24 x 1” set screw for the other side of the mount

• A 10-24 set screw can be used on the small gear if necessary (hole needs tapped)

• A 1/4-20 x 1.25” bolt works well for the hinge pin

I’ve also included STEP files in case somebody wants to modify this for a different application; the gears are designed to be 2.1” apart. I’ve also included 30 degree helical gears, but I haven’t tested them yet.

LBRY Tags: machining; 3d printing

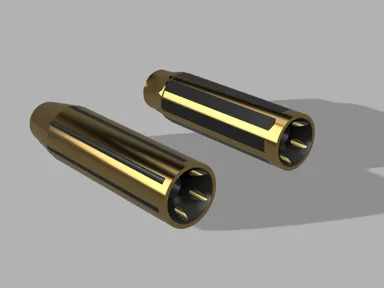

Pla_ak_ak_ak 9mm Linear Comp 1/2X28 and 3/4X10 [2/21/24]

ECM Boring Beta Version 1.0 Package (.stl files and user guide)

P2A mossberg front half stock mare's leg stock Shoulder Plate