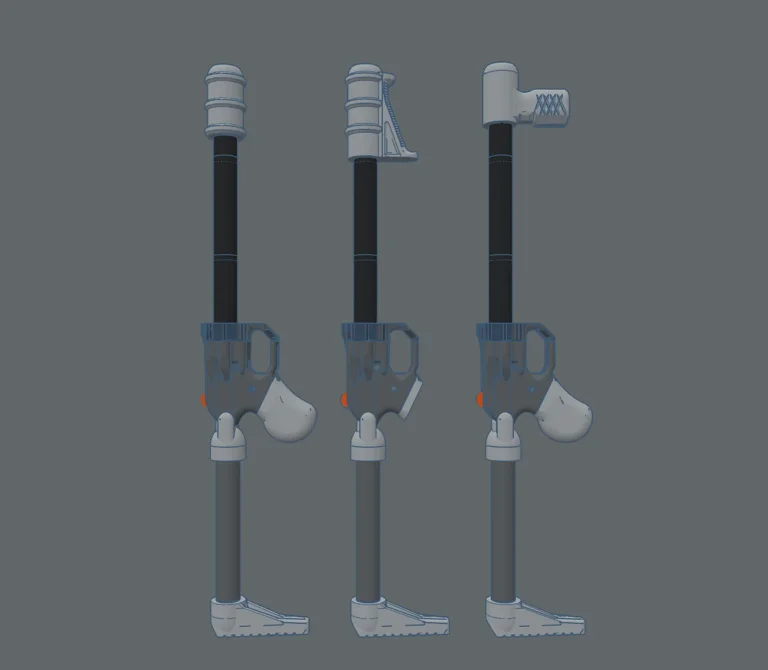

This Beta 3 release includes a rear stock that integrates a cheap $2 length of PVC pipe.

Stock adapter epoxies on rear of receiver. Thread on PVC pipe length. Thread on rear stock.

New stock adapter and rear stock are no supports prints. Only the grip needs, and includes, supports.

Receiver firing pin hole has been increased to 3.2mm; the curved back has been flattened slightly.

Increased clearance on clip mount. Now holds the pipe 6mm farther away from mounted surface.

These build instructions parallel the "Songbird PM4C General Assembly" guide.

Like the original, this is a "primarily printed" design -- no firearm parts kit.

Everything needed is either 3D printed, or found local, from any Lowes or Home Depot.

Without a rear stock, the minimum legal length barrel for this design, is a 24" (two foot) length of gas pipe.

When using the included rear stock, the minimum legal length barrel is a 18" (eighteen inch) length of gas pipe.

From tip of barrel, to rear of receiver or stock, must have an overall length of 26" (twenty six inches) minimum.

As this is only a beta, no one is expected to get a short-barrel shotgun (SBS) tax stamp, which requires months.

Most states also have firearm tracability requirements, meaning you need to get the 3D printed receiver, a serial number.

Type 7 FFLs provide the service of a new serial number, on a new and unassembled 3D printed firearm receiver.

Don't catch a charge, because you had GSR on the wrong length of pipe, or an unserialized assembled shotgun.

Required 3D printed parts (60mm/sec avg print speed):

(A1) ReceiverFrameBack.stl - (11hrs @ 0.15mm layers, 20 walls/perimeters, 100% infill, 141g filament)

(A2) ReceiverFrameFront.stl - (3.8hrs @ 0.15mm layers, 20 walls/perimeters, 100% infill, 46g filament)

(B) FiringPinRetainer.stl - (50min @ 0.10mm layers, 20 walls/perimeters, 5g filament)

(C) SafetyPullTab.stl - (11min @ 0.10mm layers, 20 walls/perimeters, 2g filament)

(D) HalvedPin.stl - (4 copies, 33min @ 0.10mm layers, 20 walls/perimeters, 5g filament)

(E) Trigger.stl - (34min @ 0.15mm layers, 20 walls/perimeters, 8g filament)

(F) Hammer.stl - (1.9hr @ 0.15mm layers, 20 walls/perimeters, 21g filament)

Optional 3D printed grips and accessories:

(G) RaptorGrip.stl - Slide on grip, designed as the default for this shotgun receiver.

(H) GripTemplate.stl - Slide on grip template, allowing anyone to design their own grip.

(I) AngledForeGrip.stl - Thread on foregrip, attaches to far end of NPT gas pipe barrel.

(J) VerticalForeGrip.stl - Thread on foregrip, attaches to far end of NPT gas pipe barrel.

(K) RibbedForeGrip.stl - Thread on foregrip, same as above AFG, without the angled part.

(L) PipeClampMount.stl - Snap on pipe clip, store out of sight, with quick pull access.

(M) RearStockAdapter.stl - Epoxy adapter to receiver rear, thread on cheap PVC pipe.

(N) RearStock.stl - Thread to other end of cheap PVC pipe, as recoil pad.

Hardware store parts (much lower cost per unit, when buying in bulk):

Required: 1x length of 3/4" steel NPT gas pipe ($Varies, Lowes): thread-on 12ga barrel.

Required: 1x box 4D common steel nails (330qty, $6.99, Lowes): used as firing pin, and both pivot pin cores.

Required: 1x bag of assorted rubber bands (200qty, $2.99, OfficeMax): used for the hammer, and trigger return.

Required: 1x pack of #8-32 x 2 inch steel bolts (6qty, $3.35, Lowes): combines printed receiver front and rear.

Optional: 1x length of 3/4" PVC gas pipe ($2.10, Lowes): thread-on between stock adapter and rear stock.

Required hand tools and other supplies:

1. Wire cutters. Needle nose pliers with built-in wire cutters will work. Needed to cut nails to length.

2. Power screwdriver. Because you don't want to turn those six bolts, 128 half-turns each, to install them.

3. Super/CA glue and/or JB Weld epoxy. Needed to assemble the 3-piece hammer, and secure the steel bolts.

4. Sandpaper or metal file. Use 60 to 200 grit to chamfer the tip, of the 4D common steel nail, firing pin.

5. Two pennies. Use glue, and insert the pennies into the hammer head, to serve as rear blade sights.

6. Small diameter wire or safety pin. 1mm galvanized wire works best, to lock the receiver pivot pins.

7. Piece of transparent filament. Glue in a 0.5" piece of filament as the front 'day-glo' sight.

Recommend 0.6mm hardened steel nozzle ($7).

Recommend PETG for mechanical parts ($14/1kg), PETG-CF for receiver ($20/1kg).

Recommend 0.15mm layers for receiver, trigger, and hammer. Recommend 0.10mm layers for pins, safety, firing pin retainer.

Recommend JB-Weld 24hr epoxy for receiver assembly ($7/2oz, $18/10oz), smushed in receiver rear breech face bolt holes.

Feedback & Test Results: https://www.reddit.com/r/ProletariGatCAD

Designer Contact: mailto:rrab@tuta.com

LBRY Tags: 3d2a; guncad

PilotGeek's Maverick v2.4

DB9 Smoothed

Null-22 BOM