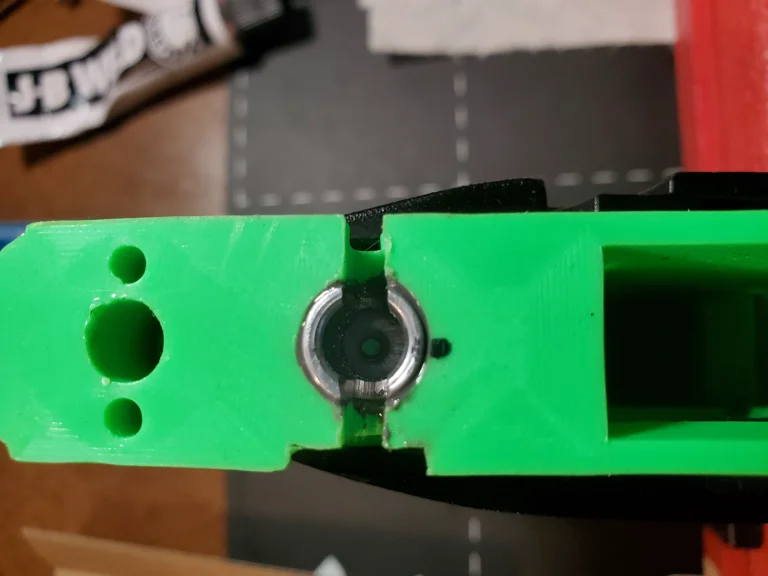

A jig to cut a sear sleeve from a common 1/4"ID x 3/8"OD x 1/2" length solid machine bushing to insert into the frame of the Big-Point. I found these bushings at my local small town hardware store at low cost. I cut the slots out with a grinding wheel on a Dremel. It may also fit the Lo-Point, but I don't have one to try it on. Prevents the sear from binding in the plastic due to the tremendous side loading of the trigger system. You can drill your frame with a 3/8" bit and install it, Or please feel free to add this cavity directly to your models before printing. Also, you can use this as a test print for sizing before you print the whole frame. Now uploaded in .stl format

u/Eastern_Cod3948 · 2025-01-24 03:27:43 UTC · score 4

I'd bet that your sear is tipping to the right, causing the bottom edge to dig into the plastic, because the HP trigger mechanism puts the load way out on the end of a pin. The factory frames seem to have a metal insert that the sear sits in, you need to replicate that for a better trigger. Che…

u/Eastern_Cod3948 · 2025-01-14 03:51:49 UTC · score 1

It sails the sea now as "Big-Point's Sear Saver"

I messaged you back.

the file is only for the Jig to aid in cutting the bushing. Use and modify in the spirit of FOSS.

u/Eastern_Cod3948 · 2025-02-09 04:36:12 UTC · score 3

If you find your trigger function sucks hard, look into do the steel insert for the sear, like the factory frames have. Look at "Big-Point's sear saver" on the sea. It helps, but it's still designed by Hi-point.

furikake v1.5 11.5" & 16" shroud (beta)

3 Slot Mlok Pack-Jackmnb

Christmas Forever - night stalker safariland qls