Where I come from it's easy to acquire 9mm Luger ammunition, but subsonic ammo is difficult to come by and extremely expensive (1,50 USD per round).

So I found a solution: cheap 3D printed PLA (preferably) molds!

Here are the details:

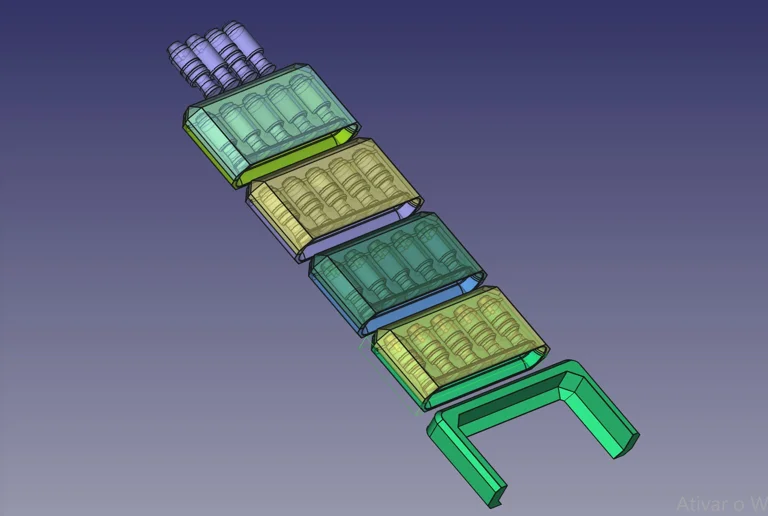

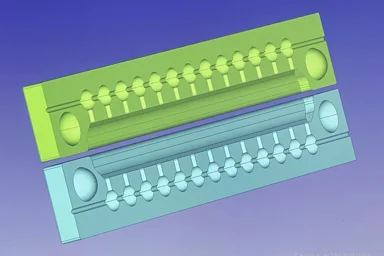

- Each pair of molds (sides A and B) have been slimmed down to only 28 grams, and must be printed with exclusive slicing tolerances, 0,4mm or better nozzle and dynamic quality or better for greater accuracy of the cast projectiles;

- These molds can only be used once, but with 5 projectiles produced with each pour, 1 Kg of cheap PLA will give 175+ projectiles at about 0,12 USD each;

- After using a sizing dye to ensure regular diameter, the plain projectiles (which I have already produced, loaded and tested up to 4,5 grains of smokeless gunpowder) will weight 167-171 grain and be reliably subsonic;

- There projectiles are entirely unjacketed, but the velocities achieved should not required a metal jacket. If you have doubts, used the appropriate molds for projectiles with grooves for wax lubricants;

- I have not tested the Hollow points (my country´s laws forbid it, so I won´t be screwing around on that front).

Have fun and don’t blow yourselves up!

LBRY Tags: reloading; fosscad; ammunition; metalcasting; 3d printing

M6/M7-Type Pressure-Traction Firing Device

M1A1- type Pressure Firing Device

00 Buckshot Mold Project