View this release

Alternative links

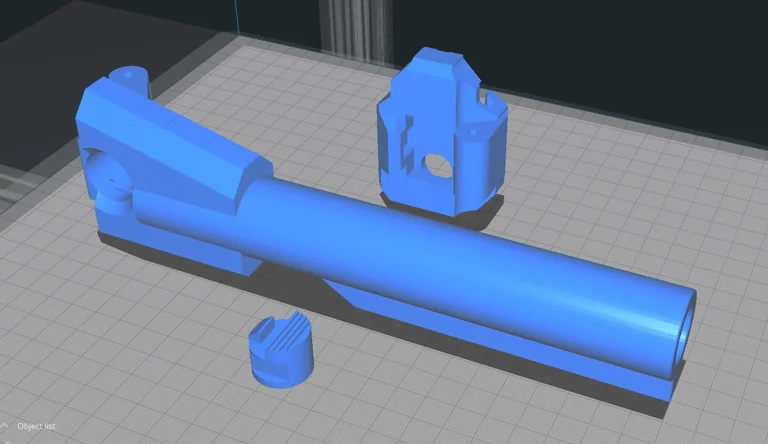

here is a design that i remixed from the AWCY Scorpion Evo Folding Stock. It transitions from the hinge to a milspec "buffer tube" to allow attaching a SBA3 brace, or any milspec buffer tube compatible brace or stock.

sliced using Cura, printed on my Artillery Sidewinder X1

With an SBA3 mounted, it allows for 4 length of pull adjustments.

The "buffer tube" is situated low enough that it is capable of firing with the stock folded, with no interference to brass ejection.

I printed mine in PETG, but PLA or PLA+ should also work. I would recommend printing this with at least 80% infill.

I recommend printing the main "buffer tube" piece at a 30 degree angle from vertical (60 degrees from the bed). This orientation allows for some layers to completely encircle the holes for the hinge pin (giving strength to this area), while preventing any deformation of the buffer tube (i tried to print the buffer tube horizontally, and it ended up not perfectly circular). I recommend using brim supports, touching build plate, for the "buffer tube" piece when printing in this orientation.

the hinge plate piece is probably strongest printed upright, as this also gives full layer encirclement of the hinge pin holes.

for the button, i printed mine flat for ease, but printing at some sort of angle would probably increase strength of the part.

LBRY Tags: 3d printing; awcy; sba3; scorpion

sliced using Cura, printed on my Artillery Sidewinder X1

With an SBA3 mounted, it allows for 4 length of pull adjustments.

The "buffer tube" is situated low enough that it is capable of firing with the stock folded, with no interference to brass ejection.

I printed mine in PETG, but PLA or PLA+ should also work. I would recommend printing this with at least 80% infill.

I recommend printing the main "buffer tube" piece at a 30 degree angle from vertical (60 degrees from the bed). This orientation allows for some layers to completely encircle the holes for the hinge pin (giving strength to this area), while preventing any deformation of the buffer tube (i tried to print the buffer tube horizontally, and it ended up not perfectly circular). I recommend using brim supports, touching build plate, for the "buffer tube" piece when printing in this orientation.

the hinge plate piece is probably strongest printed upright, as this also gives full layer encirclement of the hinge pin holes.

for the button, i printed mine flat for ease, but printing at some sort of angle would probably increase strength of the part.

LBRY Tags: 3d printing; awcy; sba3; scorpion