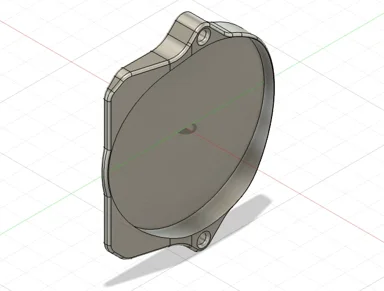

Weighted printable 40mm pusher and windscreen compatible w/ KAK zinc pushers. Designed to accept 1 1/4" fender washers to add mass into the center of the pusher bring its weight to 130g (vs the zinc 155g). STLs and STP included. Remix friendly!

Intended to be used w/ chalk or any other powder marker. Compatible w/ full power lift charges. See README for more.

edit: in case it is not something considered, the thin nose'd windscreen is designed to be scraped off the print bed. this allows for the thinnest setup possible and guarantees rupture on impact. The thicker nose'd windscreen is designed to be popped off the bed same as every other pla print. I will also add this to the readme tomorrow since there were questions on reddit...

file update:

09.21.25a: increased upper pusher chamber thickness to increase likelihood of washer retention upon impact.

09.21.25b: Uploaded the actual file for the upper pusher chamber thickness because I suck. Thumbnail changed to demonstrate new chamber ceiling thiccness.

09.23.25: PLEASE check the slicer before hitting send. I will include my 3mf that I am going to be using but turns out bridging doesn't happen properly with greater than four walls and an 0.6mm nozzle, so please please please print at max 4 walls for 0.6mm nozzles. >4 walls is fine for 0.4mm nozzles. The rest can just be VERY high density walls or bottom layers. Will addend the readme as well.

09.27.2025: addended readme, included photos of completed pusher and windscreen vs machined variant. Renamed thin nose windscreen with instructions in the part name.

LBRY Tags: 3d2a; guncad; 40mm; windscreen; pusher

M34 White Phosphorus Smoke Grenade Body

PINUS Instant Light Emitter Christmas Tree Grenade

HubTN.4 - Assembly Jig (v1)