View this release

Alternative links

WARNING ⚠️: This is a NFA item, testing was done by a licensed SOT and Texens where they are legal to own. Know your local laws before printing this device. **If you would like to support the work i do you can buy the same files from Defcad or Donate LBC or to my BTC at 1AEbR1utjaYu3SGtBKZCLJMRR5RS7Bp7eE **

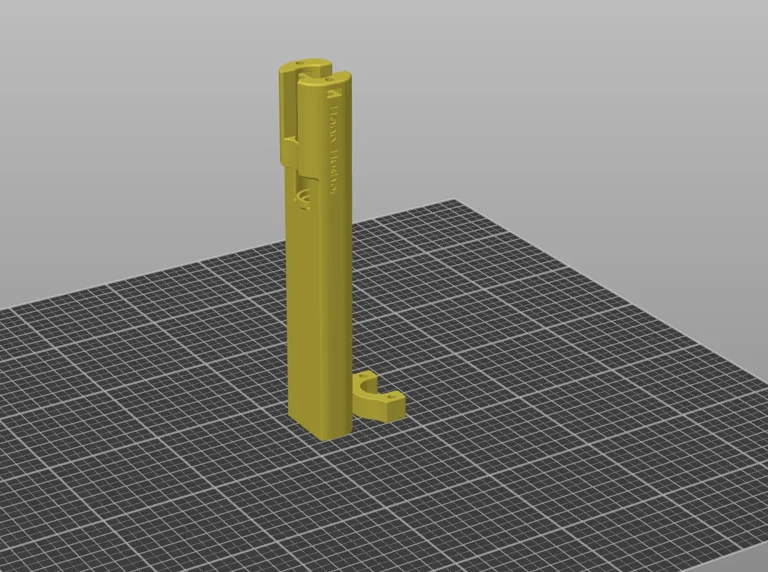

Henry Husher: A Henry H001 Suppressor

Original Developer: nameisnight

The goal of the project is to make a suppressor for the Henry H001 that does not need any modification to the gun and keeps the original magaizne tube usable while attached.

Needed Hardware:

2 x M3x20mm Screws

2 x M3 Nuts

1 x 9.8x2.4mm (P10A) O-Ring - OPTINAL

Files to print:

1 x Suppressor Type (A or B)

1 x Barrel Band Type (A or B)

Print Settings:

PLA+ or Better

210c Hotend

55c Bed

.20 layer hight

Minimum 3 Walls

Max infill (Has been tested with 5.5% gyroid without issue...)

Supports on build plate only

Assembly:

1. Remove Outer Magazine Tube.

2. Place an O-ring in the suppressor where the barrel will interface.

3. Carfully slide suppressor onto barrel with the smaller bottom part between the barrel and the magazine tube, Make sure its pressed on the O-ring.

4. Put M3 nuts into the left and right slots of the suppressor and place the barrel band over the barrel, Put the M3x20mm screws through the barrel band and screw them into the nuts on the suppressor.

5. Tighten the mounting screws with even pressure.

6. Replace Outer Magazine Tube.

Warnings:

This is a NFA item. Know your laws!

Check for cracks often, If ANY are found despose of suppressor and make a new one.

Don't use hypersonic ammunition!

NOTES:

The barrel mockup is not to spec! This is an example of how to mount the suppressor. Visual only.

The file "H001 Suppressor Mount Only" is the CAD of the mount up to where the barrel of the gun meets the device, to allow the user to make custom baffles, bodies, etc.

Barrel Bands and Suppressor Types are interchangable, The Suppressors are the same otherthen baffle design. Barrel bands have a different pressure point for mounting and support the O-ring better.

Use Blue Locktight on the mounting screws to help keep them from backing out.

Alternitively, you can use a 8.8x1.9MM (P9) O-Ring as it will allow a more 'flush' barrel interface while. But will offer less then perfect gas seal.

Sub-Sonic Ammo recommended, Standard Voloicty acceptable.

LBRY Tags: 3d printed; suppressor; defcad; fosscad; awcy

Henry Husher: A Henry H001 Suppressor

Original Developer: nameisnight

The goal of the project is to make a suppressor for the Henry H001 that does not need any modification to the gun and keeps the original magaizne tube usable while attached.

Needed Hardware:

2 x M3x20mm Screws

2 x M3 Nuts

1 x 9.8x2.4mm (P10A) O-Ring - OPTINAL

Files to print:

1 x Suppressor Type (A or B)

1 x Barrel Band Type (A or B)

Print Settings:

PLA+ or Better

210c Hotend

55c Bed

.20 layer hight

Minimum 3 Walls

Max infill (Has been tested with 5.5% gyroid without issue...)

Supports on build plate only

Assembly:

1. Remove Outer Magazine Tube.

2. Place an O-ring in the suppressor where the barrel will interface.

3. Carfully slide suppressor onto barrel with the smaller bottom part between the barrel and the magazine tube, Make sure its pressed on the O-ring.

4. Put M3 nuts into the left and right slots of the suppressor and place the barrel band over the barrel, Put the M3x20mm screws through the barrel band and screw them into the nuts on the suppressor.

5. Tighten the mounting screws with even pressure.

6. Replace Outer Magazine Tube.

Warnings:

This is a NFA item. Know your laws!

Check for cracks often, If ANY are found despose of suppressor and make a new one.

Don't use hypersonic ammunition!

NOTES:

The barrel mockup is not to spec! This is an example of how to mount the suppressor. Visual only.

The file "H001 Suppressor Mount Only" is the CAD of the mount up to where the barrel of the gun meets the device, to allow the user to make custom baffles, bodies, etc.

Barrel Bands and Suppressor Types are interchangable, The Suppressors are the same otherthen baffle design. Barrel bands have a different pressure point for mounting and support the O-ring better.

Use Blue Locktight on the mounting screws to help keep them from backing out.

Alternitively, you can use a 8.8x1.9MM (P9) O-Ring as it will allow a more 'flush' barrel interface while. But will offer less then perfect gas seal.

Sub-Sonic Ammo recommended, Standard Voloicty acceptable.

LBRY Tags: 3d printed; suppressor; defcad; fosscad; awcy